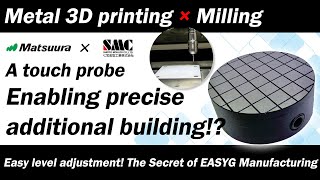

[Metal 3D printing×Milling] A touch probe enabling precise additional building

2025/06/27

This is a case study from Shippo Molds Industry Co., Ltd., a LUMEX user.

Thanks to its built-in spindle, LUMEX enables highly accurate positioning through probing.

Leveraging this advantage, the company developed a fixture called “EASYG”, which allows anyone to easily level workpieces.

With the power of the LUMEX spindle, new possibilities in manufacturing are unlocked!